Silicon Based Anodes

Silicon Based Anodes

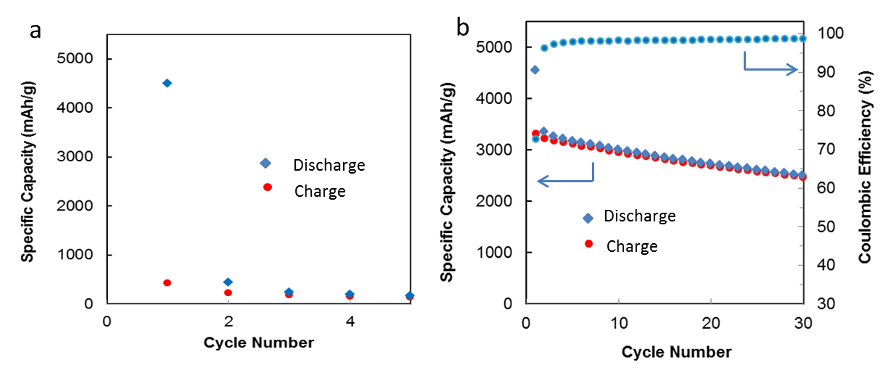

Silicon alloys have the highest specific capacity when used as anode material for lithium-ion batteries, however, the drastic volume change inherent in their use causes formidable challenges toward achieving stable cycling performance. Large quantities of binders and conductive additives are typically necessary to maintain good cell performance.

Projects

Featured Publications

Zhu, Tianyu, and Gao Liu."Communication—Functional Conductive Polymer Binder for Practical Si-Based Electrodes."Journal of The Electrochemical Society

168.5 (2021) 050533. DOI

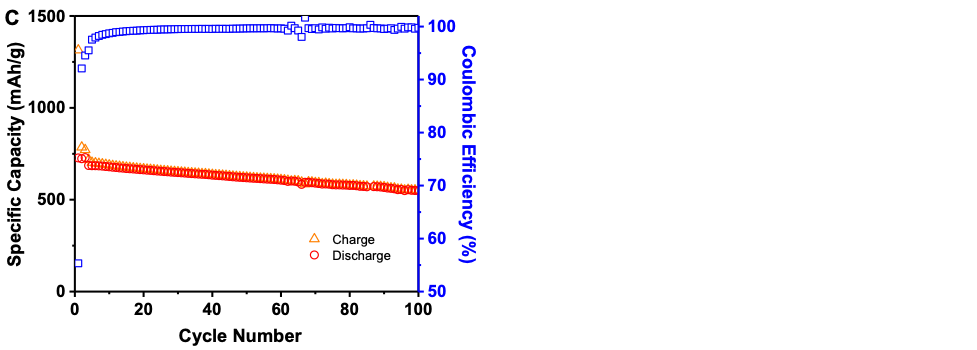

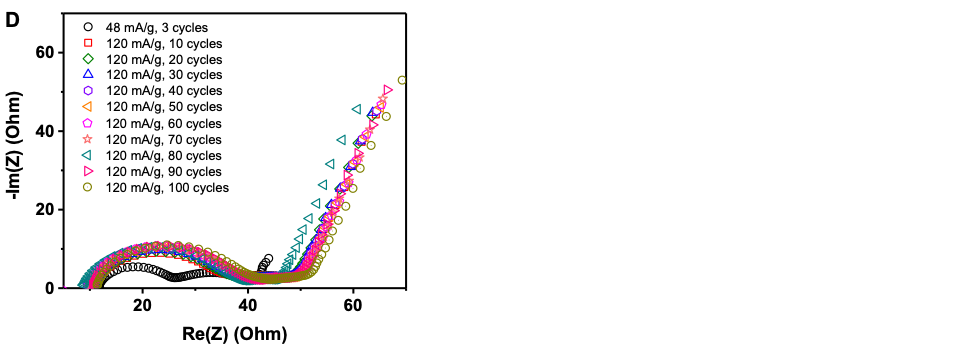

Zhao, Hui, Zhihui Wang, Peng Lu, Meng Jiang, Feifei Shi, Xiangyun Song, Ziyang Zheng, Xin Zhou, Yanbao Fu, Guerfi Abdelbast, Xingcheng Xiao, Zhi Liu, Vincent S Battaglia, Karim Zaghib, and Gao Liu."Toward practical application of functional conductive polymer binder for a high-energy lithium-ion battery design."Nano Letters

14 (2014) 6704–6710. DOI

Xun, Shidi, Bin Xiang, Andrew M Minor, Vincent S Battaglia, and Gao Liu."Conductive Polymer and Silicon Composite Secondary Particles for a High Area-Loading Negative Electrode."Journal of The Electrochemical Society

160.9 (2013) A1380-A1383. DOI

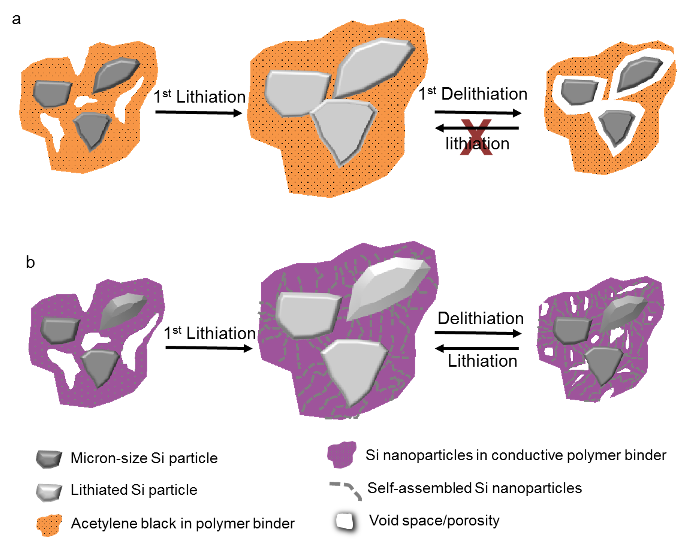

Wu, Mingyan, Julian E. C Sabisch, Xiangyun Song, Andrew M Minor, Vincent S Battaglia, and Gao Liu."In Situ Formed Si Nanoparticle Network with Micron-Sized Si Particles for Lithium-Ion Battery Anodes."Nano Letters

13 (2013) 5397-5402. DOI

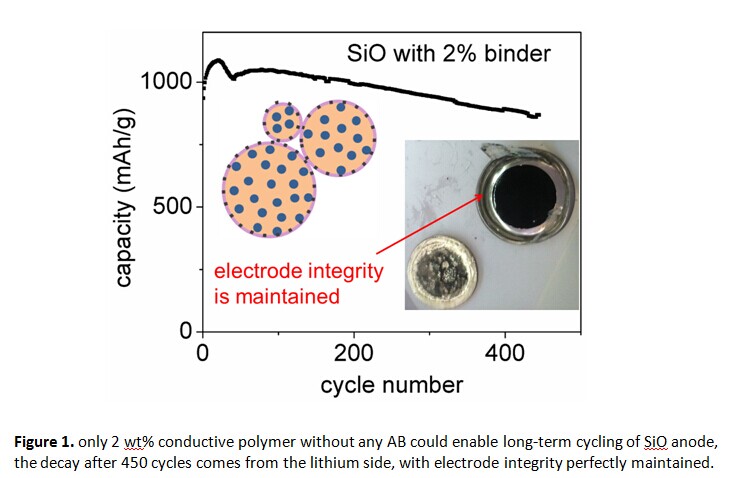

High Energy Density Silicon Monoxide Anode

High Energy Density Silicon Monoxide Anode