Methodologies

Methodologies

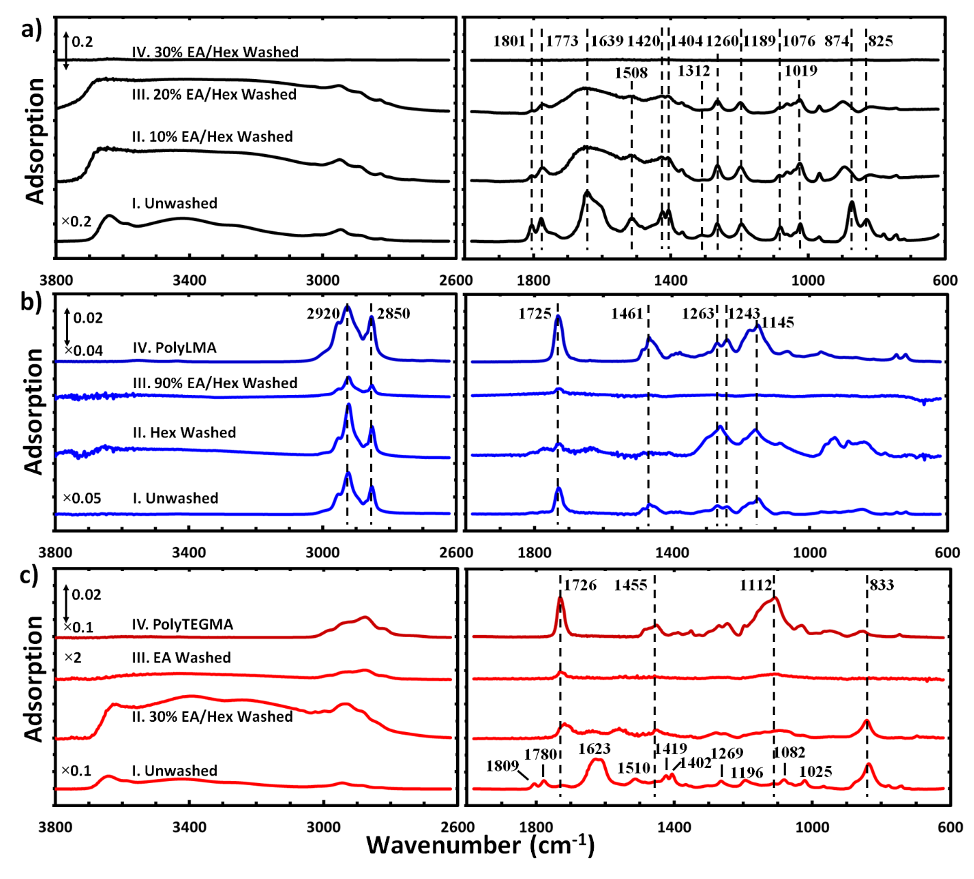

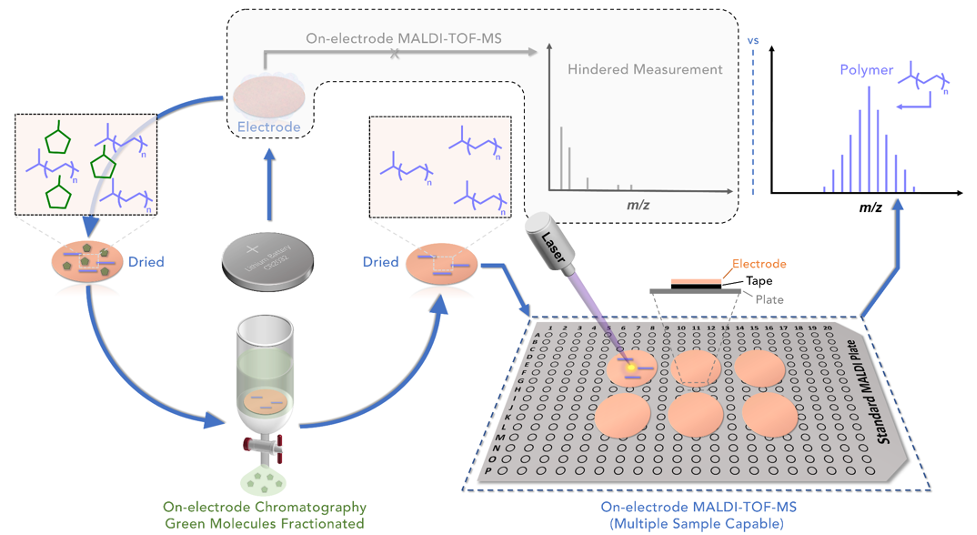

Exploration of new materials and chemistry has always been a hotspot in battery research. The methodology to study essential materials & interface properties, mechanisms of chemical & physical processes, as well as the materials manufacturing & processing involved in battery fabrication plays a very important role in improving battery performance. The Liu Lab group is currently investing in developing advanced methods for both liquid and solid state batteries and enabling methodology to study the evolution of organic species in solid state interphase (SEI) composition by utilizing our freshly minted gradient wash method integrated with IR and MALDI techniques.

Projects

Featured Publications

Fang, Chen, Zhimeng Liu, Jonathan Lau, Mahmoud Elzouka, Guangzhao Zhang, Piyachai Khomein, Sean D Lubner, Philip N Ross, and Gao Liu."Gradient Polarity Solvent Wash for Separation and Analysis of Electrolyte Decomposition Products on Electrode Surfaces."Journal of The Electrochemical Society

167.2 (2020) 020506. DOI