Electrode Binders

Electrode Binders

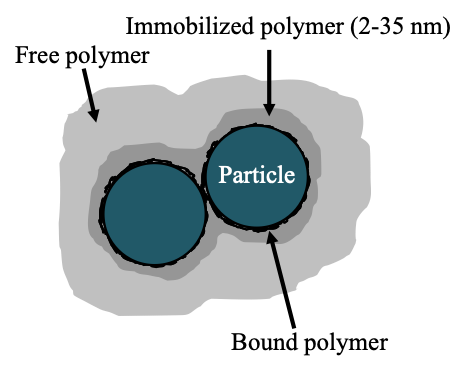

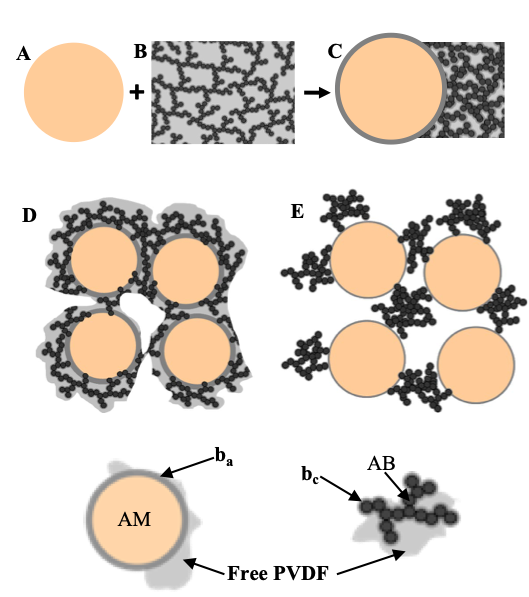

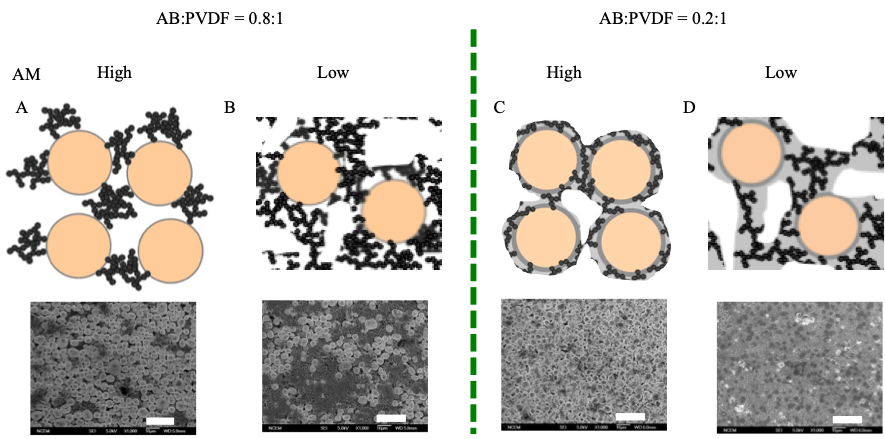

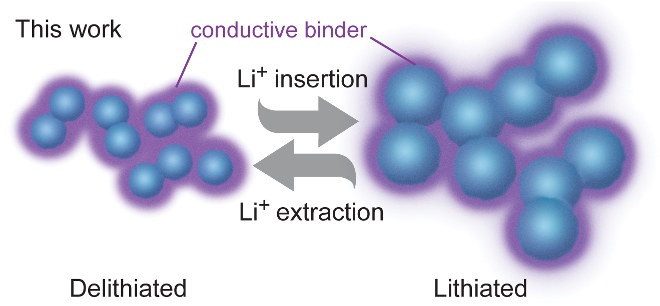

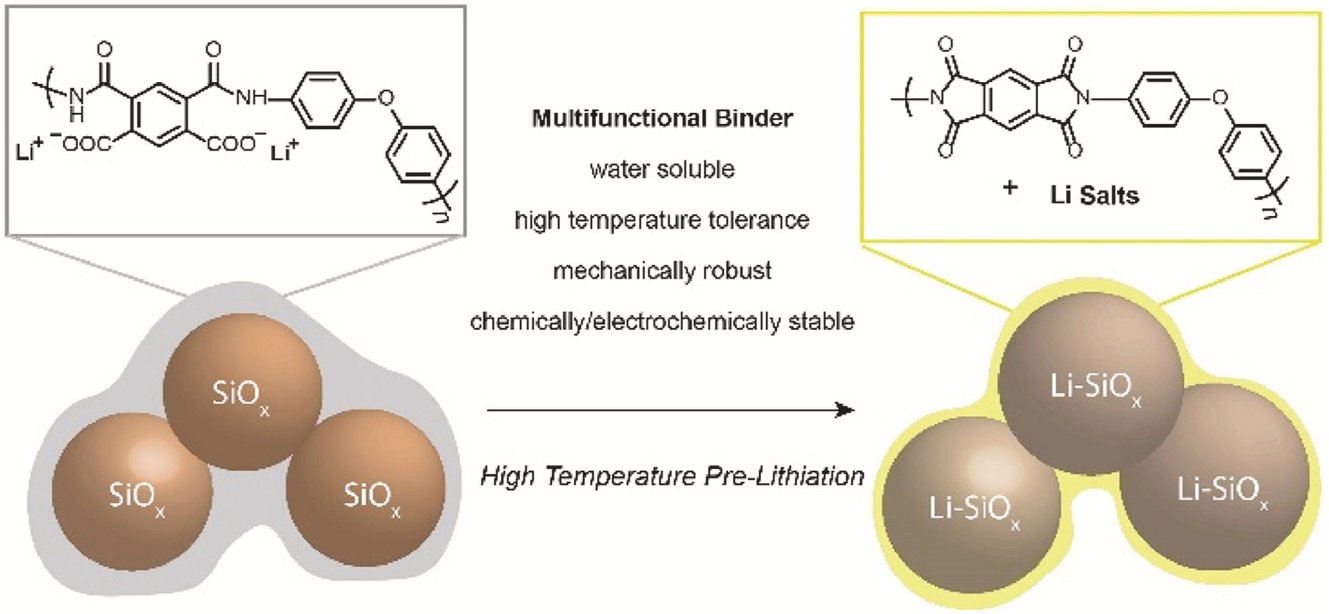

Polymer adhesive binders are important components of modern lithium-ion electrodes. Small amounts of polymer binders along with electrode particles and conductive additive particles form a unique polymer composite electrode. The polymer binder ensures mechanical integrity and a stable microstructure of the electrode, and maintains ion and electron pathways within the composite.

Projects

Featured Publications

Zhu, Tianyu, Thanh-Nhan Tran, Chen Fang, Dongye Liu, Subramanya P Herle, Jie Guan, Girish Gopal, Ajey Joshi, James Cushing, Andrew M Minor, and Gao Liu."Lithium substituted poly(amic acid) as a water-soluble anode binder for high-temperature pre-lithiation."Journal of Power Sources

521 (2022) 230889. DOI

Chen, Hao, Min Ling, Luke Hencz, Han Yeu Ling, Gaoran Li, Zhan Lin, Gao Liu, and Shanqing Zhang."Exploring Chemical, Mechanical, and Electrical Functionalities of Binders for Advanced Energy-Storage Devices."Chemical Reviews

118.18 (2018) 8936 - 8982. DOI

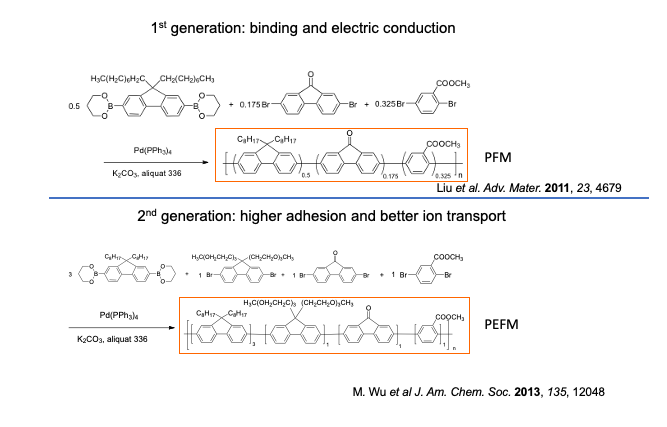

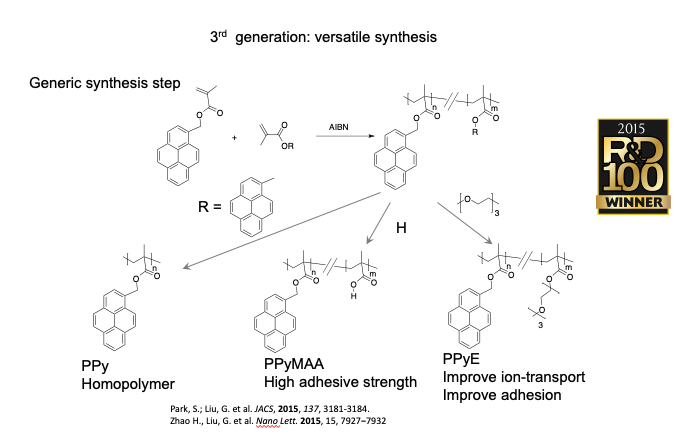

Park, Sang-Jae, Hui Zhao, Guo Ai, Cheng Wang, Xiangyun Song, Neslihan Yuca, Vincent S Battaglia, Wanli Yang, and Gao Liu."Side-Chain Conducting and Phase-Separated Polymeric Binders for High-Performance Silicon Anodes in Lithium-Ion Batteries."Journal of the American Chemical Society

137.7 (2015) 2565 - 2571. DOI

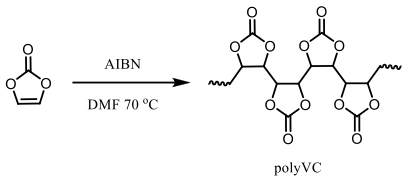

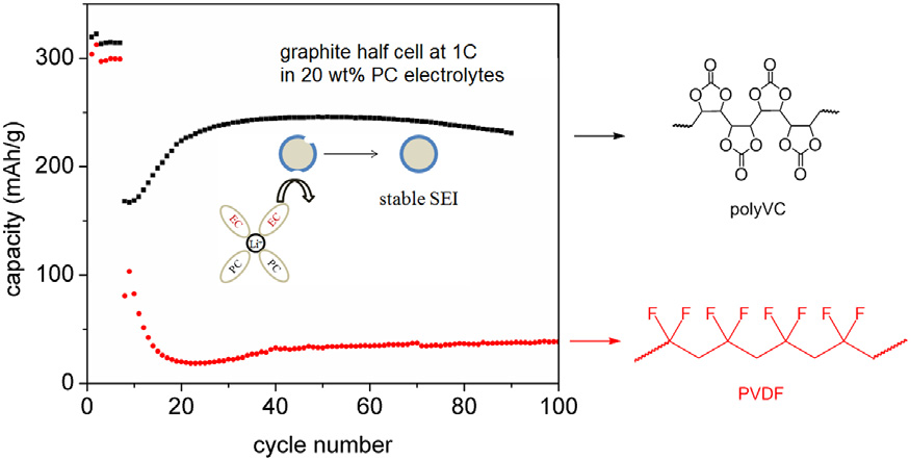

Zhao, Hui, Xin Zhou, Sang-Jae Park, Feifei Shi, Yanbao Fu, Min Ling, Neslihan Yuca, Vincent S Battaglia, and Gao Liu."A polymerized vinylene carbonate anode binder enhances performance of lithium-ion batteries."Journal of Power Sources

263 (2014) 288-295. DOI

Ling, Min, Jingxia Qiu, Sheng Li, Hui Zhao, Gao Liu, and Shanqing Zhang."An environmentally benign LIB fabrication process using a low cost, water soluble and efficient binder."Journal of Materials Chemistry A

1.38 (2013) 11543-11547. DOI

Liu, Gao, Shidi Xun, Nenad Vukmirovic, Xiangyun Song, Paul Olalde-Velasco, Honghe Zheng, Vincent S Battaglia, Linwang Wang, and Wanli Yang."Polymers with tailored electronic structure for high capacity lithium battery electrodes."Advanced Materials

23.40 (2011) 4679-4683. DOI